Falls Industrial Foam Materials

Durable Polyurethane and Polyethylene Foam

Complete projects of any size and meet your clients' deadlines with an array of manufacturing products from Falls Industrial Foam in Little Falls, Minnesota. We are an ever evolving foam fabrication company offering an abundant selection of foam types including: polyurethane and polyethylene. From 3-D urethane to thermo-molding crosslinks, we offer a variety of foam and coating products useful in a wide range of foam converting applications. Here is a brief list of the materials we handle and distribute.

Materials

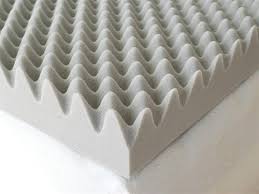

Polyurethane

- Conventional Foams

- Fire Retardant Foams

- HR Foams

- Cal Materials

- Rebonded Foams

- Anti-Static Foams

- Visco elastic (GEL) memory foams

- HyPUR Cell (T-1515)

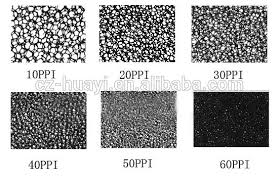

- Thermally Reticulated Polyether Foams (Hyper-DRI)

RB1

- A water resistant material that gets wrapped around polyurethane foam

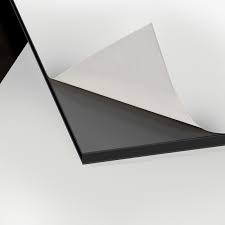

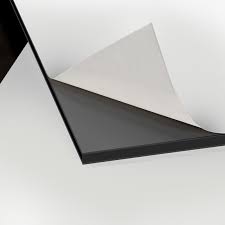

Pressure Sensitive Adhesives (PSA)

- Variable levels of tack

- Thicknesses ranging from 3 mil. To 5 mil.

Polyester

- Fiber Fill (“Dacron”)

- Low Permeability Foams

- Oil Absorbent Foams

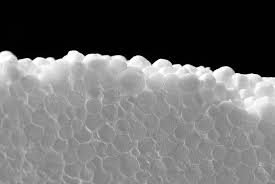

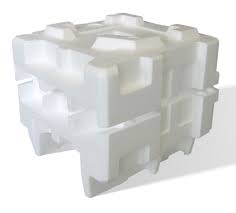

Polystyrene (“Styrofoam”)

- Expanded polystyrene

Polypropylene

- Expanded polypropylene

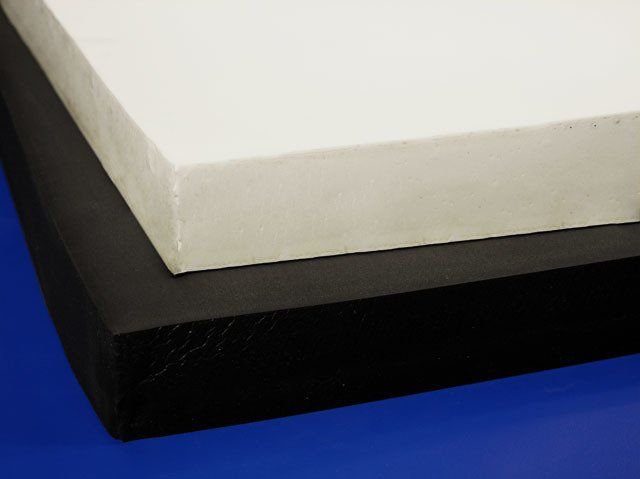

Polyethylene

- Expanded polyethylene

- Crosslinked polyethylene

- Crosslinked polyethylene with EVA

- Anti-static

- Extruded and Laminated Planks

Rubbers

- Neoprene

- Ensolite MLC (sponge Rubbers)

- PVC’s

Material Learning Center

POLYETHYLENE

foams are a resilient closed-cell foam. They are strong and ideally suited for products that require buoyancy, shock absorption, vibration dampening and insulation. It has characteristics that provide optimal cushioning protection against repeated impacts. Because of the several varieties of densities and material types, it is one of the leading medical foams in the industry. Listed below are some of the added values of the polyethylene foams.

Closed Cell Polyethylene Foam

Lightweight

Shatter proof

Cost-effective

Easy to fabricate

Great buoyancy

Excellent strength, and tear resistant

Shock absorbing

Flexible

Resistant to mildew, mold, rot, and bacteria

Superior chemical & grease resistance

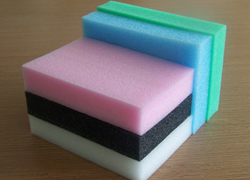

CROSS-LINKED POLYETHYLENE

foam is a closed cell polyethylene foam that has been chemically cross linked and is water resistant. It creates a smoother, more appealing feel with greater physical and chemical properties as opposed to a standard polyethylene foam.

This foam is offered in multiple varieties of densities and colors. It is also available in anti-static, conductive, and fire retardant formulations.

Utility-Based Foam Types

Polyethylene foams are rugged and unusually resistant to many chemical solvents. It is used in a wide variety of applications such as packaging, labeling, and reusable containers of various types. Cross-linked polyethylene foam is another closed cell foam that has been chemically cross linked. It combines a smoother aesthetic feel with superior physical and chemical properties than standard polyethylene foam. This foam is available in a wide range of densities and several different colors. It is available in anti-static, conductive, and fire retardant formulations.

Coating Products

At Falls Industrial Foam we use Plasti-Dip as our main supplier of coating products. The coating has a variety of different colors and finishes and can be done on both open and closed-cell foams. The medical industry uses these coatings because they are reusable and resistant to many cleaning chemicals. Coating makes our products easy to clean because it eliminates textures and ridges that can hold bacteria. Applying coating also forms a barrier that repels liquid contaminants. The coatings can be applied by spraying and dipping.

Contact us today if you are a manufacturing or packaging company looking for the highest quality polyurethane products around.